Documentation >

MAC-PAC Technical Library >

Manufacturing >

Requirements Planning >

Programs >

Requirements Planning Generation for JIT Parts - Purpose

Requirements Planning Generation for JIT Parts - Purpose

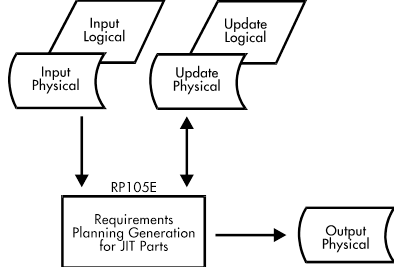

RP105E

The Requirements Planning Generation for JIT Parts program (RP105E) develops an optimal replenishment plan for Just-in-Time manufactured or build-through parts. Each part is processed according to its location in the bill of material. Daily requirements for the parts are analyzed and an optimal daily production schedule is generated to meet the requirements. There are two methods for generating the production schedule: partial and average rate planning. Under the partial rate planning method, analysis plans supply rates to exactly meet the outstanding demand quantities in a flow interval. With the average rate planning method, analysis begins by accumulating all outstanding demand in the flow interval. Supply is then planned by calculating the average supply rate for the interval. The production schedule is implemented as flow authorizations (FAs). FAs are maintained (added, changed, or deleted) as needed to ensure that the optimal replenishment plan is generated. Days that fall within a part’s firm horizon will have action messages if the production rate does not equal the optimal replenishment rate. The action messages generated are increase and decrease. Requirements Planning Generation for JIT Parts is called by the Requirements Planning Generation program (RP100E) whenever a part with a production type of JIT and a part type of manufacture or build-through is retrieved. Processing will continue until a part is retrieved with a production type of MRP, or a part type of purchase or raw material. This program will run in both actual and/or simulation run mode. This permits simulated flow schedules and requirements to be generated in the same manner as the flow authorizations and flow requirements. If no simulated demand exists for a part to be planned in simulated RP run mode, then actual demand drive the planning process for the part.