Documentation >

MAC-PAC Technical Library >

Distribution >

Synchro >

Programs >

Synchro Labels Maintenance - Purpose

Synchro Labels Maintenance - Purpose

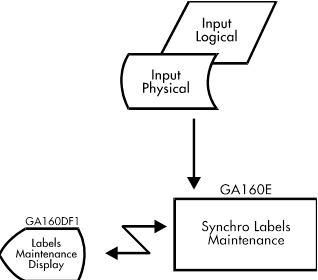

GA160E

The Synchro Labels Maintenance program (GA160E) allows the user to use four different types of labels. Labels are generated at the end of the manufacturing process in order to identify the items to be shipped during the packaging process. The four types of labels are as follows:

1. Packaging Unit Labels (type 1):

These labels can be generated for a specific item and quantity without the user having to give a shipping proposal number or delivery point. Like type 2 or type 4 labels, packaging unit labels are inked to a shipping list line.

2. Handling Unit Labels (type 2):

Handling units contain packaging units with only one product. Handling unit labels refer to a shipping list line and indicate the name and address of the delivery point.

3. Simplified Handling Unit Labels (type 3):

Simplified handling unit labels are both handling and packaging units. They contain the name and address of the delivery point.

4. Mixed Handling Unit Labels (type 4):

Mixed handling unit labels may have several packaging units with several products. They do not contain, therefore, any information about the items (customer item number, description, vendor item number, quantity). Every packaging unit within the mixed handling unit must be linked to a shipping list line. Mixed handling unit labels contain the name and address of the delivery point.

Labels are associated with the actual shipment in the Shipping List Maintenance conversation (GA145E, GA147E). If mixed handling unit labels are used, the user must tie each packaging unit label to one or several shipping list line(s). If normal handling unit labels are used, the packaging unit labels must be assigned to them.

Even if labels have been generated for a specific shipping proposal number, they are not automatically used on a shipping list that corresponds with this proposal number. The label is validated when it is used. Validation only occurs on the information printed on the label, such as the customer item number, the internal item number, the vendor number for the customer, and the name and address of the customer for the shipping labels (types 2–4). Synchro labels can be used, therefore, as long as all information printed on them is valid. Because packaging unit labels do not state a delivery point, they can be used for any other shipment if all the data on the label is correct. All other label types cannot be used for a different delivery point. On the Function Select screen (GA160S01), the user specifies the proposal number and the part for which the labels are to be created. If the user wants the label type to be different from the endorsement that is valid for this shipment, another type can be entered. If the user wants to generate labels for quantities different from the ones on the shipping proposal, the user must enter a new control quantity. One of several screens may appear depending on the label type:

Packaging units (PU) or simplified handling units (SHU) are created by entering any number on the PU/SHU screen (GA160S02). Packaging unit labels corresponding to the same item must be associated with a handling unit or a mixed handling unit. PU label numbers will be created automatically by the program and displayed on the screen. Entering label type 2 on the select screen will enable the user to associate PUs to a normal handling unit (GA160S03); label type 4 will let the user assign PUs to a mixed handling unit (GA160S04).

F22 validates all detail screens.