Documentation >

MAC-PAC Technical Library >

Manufacturing >

Requirements Planning >

Programs >

Requirements Planning Generation - Purpose

Requirements Planning Generation - Purpose

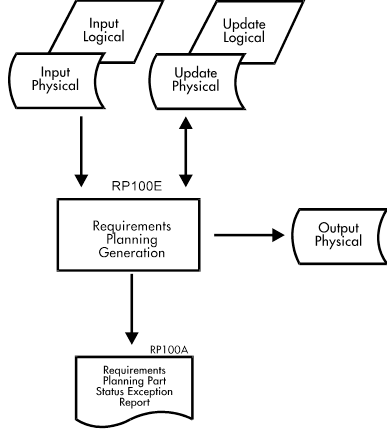

RP100E

The Requirements Planning Generation program (RP100E) develops an optimal replenishment plan to support the manufacturing process. Each part on the Part Master file (DE100M) is evaluated according to its location in the bill of material. Highest-level parts (top of bill of material) are evaluated first. Then each lower-level part is processed in descending sequence. Requirements and orders for each part are analyzed in a time-phased manner to determine whether inventory will be available (either in-stock or on-order) when needed. If the analysis reveals either time or quantity discrepancies, non-planned supply orders are highlighted with an order action message (for example, expedite to an earlier date); planned manufacturing orders, purchase requisitions, and transfer requisitions are maintained (add, change, or delete) within the part’s lot sizing rules. This action or suggested action is provided to assist the planner in developing and maintaining an optimal replenishment plan. This program will generate actual or simulated orders and requisitions, depending on the RP run mode selected by the user in the RP Request program (RP110E).