Documentation >

MAC-PAC Technical Library >

Manufacturing >

Requirements Planning >

Programs >

RP Generation for Job Controlled Parts - Purpose

RP Generation for Job Controlled Parts - Purpose

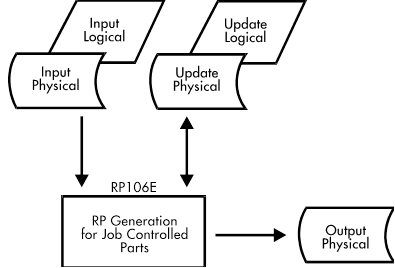

RP106E

The RP Generation for Job Controlled Parts program (RP106E) develops an optimal replenishment plan for job-controlled purchased, manufactured, raw material, or build-thru parts. The requirements and orders for each job-controlled part are analyzed in a time-phase manner to determine whether inventory will be available (either in stock or on order for the related job) when needed. If the analysis reveals either time or quantity discrepancies, non-planned supply orders for the job are highlighted with an order action message. Planned manufacturing orders and requisitions for the job are maintained (added, changed, or deleted).

RP firm horizon processing is not supported for job-controlled parts. This is because within the RP firm horizon, multiple job-based requirements may contribute to a negative projected inventory. RP is not able to plan multiple planned supply records outside the RP firm horizon date for each job-based requirement contributing to the negative projected inventory.