Documentation >

MAC-PAC Technical Library >

Manufacturing >

Just-in-Time >

Programs >

Production Schedule Maintenance - Purpose

Production Schedule Maintenance - Purpose

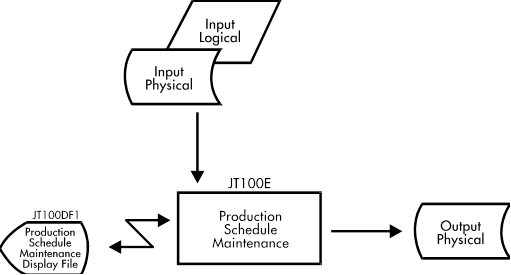

JT100E

The Production Schedule Maintenance program (JT100E) is an online maintenance program that allows you to balance either daily or weekly production quantities (flow authorization quantities) for all parts within a production center in a given plant. The production center may be a cell or assembly line. You may choose Daily or Weekly Production Schedule Maintenance from the Just-in-Time Menu. The detail screen will serve as a worksheet that will allow you to simulate a production schedule before updating the master files. Once the optimal schedule has been determined, affected flow authorizations are updated along with their flow requirements.

Flow authorization and flow requirements may be added, deleted, or changed on the respective master files. A flow authorization may occur for several reasons: change in daily or weekly production quantity, change in revision level, and change in flow interval period.

When the detail screen is displayed, the total load and the percentage of capacity in the entered production center are calculated and displayed. This will help to establish a production schedule that does not overload the production center. It is possible to display availability for a given day or week for a part produced in that production center. This will help to establish a production schedule to meet scheduled demand. Total load, percentage of capacity and availability are recalculated each time you change a daily/weekly production quantity on the screen.