Documentation >

MAC-PAC Technical Library >

Manufacturing >

Inventory Control >

Programs >

Manufacturing Order Maintenance - Purpose

Manufacturing Order Maintenance - Purpose

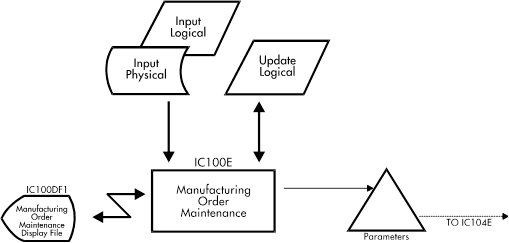

IC100E

The Manufacturing Order Maintenance program (IC100E), in conjunction with the Manufacturing Order Post program (IC102E) and the Component Requirements Generation program (IC104E), processes additions and changes to manufacturing orders and component requirements.

The Manufacturing Order Maintenance program processes the online entry and the validation of additions and changes to manufacturing orders. It produces a transaction file that is sent to the Manufacturing Order Generation program, which updates the master files with manufacturing orders and component requirements.

Component requirements can be generated when adding an order in the Manufacturing Order Post program or during the master file update of the order addition in the Manufacturing Order Generation program. In both cases, the Component Requirements Generation program is called and returns the component requirements to the Manufacturing Order Post program, for display, or the Manufacturing Order Generation program, for master file updates.

If the Shop Floor Control module is installed, labor requirements can be generated for manufacturing orders during the following types of order maintenance: adding an order, changing an open or firm order, releasing a firm or planned order, and firming a planned order.