Documentation >

MAC-PAC Technical Library >

Manufacturing >

Design Engineering >

Programs >

Product Structure Maintenance - Multi-Line - Purpose

Product Structure Maintenance - Multi-Line - Purpose

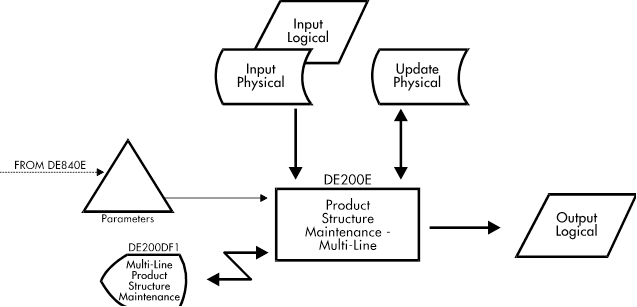

DE200E

The Product Structure Maintenance - Multi-Line program (DE200E) allows users to view and change the product structure for a part online. Processing is similar to the online update processing in the Product Structure Maintenance program (DE120E), except that the user can see all first-level components for the part while entering changes.

Once changes are entered, the program updates the Product Structure file and Part Master (for low level codes) online. Report records are written each time the files are updated. These report records provide synchronous points for recovery/restart processing, a record of data base activity by part number (Maintenance Audit Trail report), and a track of transaction entry by reference number (Transaction Register report). After a transaction is entered, any validation errors are highlighted and the appropriate error messages are displayed.

The basic processing flow for this program is as follows:

· The program displays a screen prompting the user to enter a parent part number and an effectivity date. The user can enter ALL for the effectivity date to see all the components. The user can view a list of valid values of the field prompted by pressing F4.

· Once a part number has been entered, the program displays all of the parent's single-level components that are effective as of the specified date. Information for each component is displayed on a separate line. Each line has a sequence number. This screen is called the selection screen.

· To add a new line, the user enters a sequence number and component part number to indicate where the new line should be inserted and types an A as the transaction code.

To delete a line, the user enters the appropriate sequence number and component part number and types a D.

To change a line, the user enters the appropriate sequence number and component part number and types a C.

· The program then displays a "work line" at the bottom of the bill of material. This work line allows the user to enter or change all of the product structure fields for the indicated component except BON safety stock and Delivery Frequency. When adding or changing the product structure of a SIR component (issue code 'S' or 'T'), program checks the value of the Multiple Location Backflushing flag on Reference File category 436. If this flag is set to 'Y' (Yes), program sends a warning message if the reference operation number is left blank or is set to zeros.

· The user can also press F5 to display a detail screen listing all of the information on the work line. This detail screen uses the same format as the detail screen used by the Product Structure Maintenance program. The user can press F5 again to switch back to the selection screen. Pressing F5 switches between these two screens.

· The user can press F18 to enter Bill of Material Comment Maintenance from the detail screen. BOM comments can be added to each parent part number, component part number, and sequence number combination on the product structure.