Documentation >

MAC-PAC Technical Library >

Manufacturing >

Design Engineering >

Programs >

Cumulative Leadtime Generation - Purpose

Cumulative Leadtime Generation - Purpose

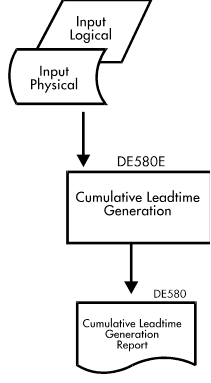

DE580E

The Cumulative Leadtime Generation program (DE580E) recalculates the cumulative lead time for each part in a plant. For purchased, raw material, and transfer parts, the cumulative lead time is the sum of all leadtimes for the part. For manufactured parts, the cumulative lead time for each of the part's components is calculated, and the longest cumulative lead time for any component is added to the setup time, run time, transit time, and fixed lead time for the parent to give the parent part's cumulative lead time.

The Part Master file (DE100M) is updated with the new lead time, and a record is written to the Cumulative Lead Time Generation report (DE580). Requests for lead time generation are entered through the Cumulative Lead Time Generation Request program (DE350E) and stored on Reference File category K11.