Documentation >

MAC-PAC Technical Library >

Distribution >

Purchasing >

Programs >

Receipt Quantity Control - Purpose

Receipt Quantity Control - Purpose

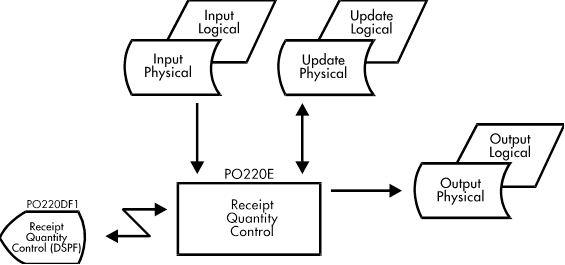

PO220E

The Receipt Quantity Control program (PO220E) records the purchase order receipts and performs the updates of the stock balances. If the receipt was not already recorded in the Purchase Order Receipt program (PO210E), purchase order lines are proposed against which receipts may be applied. If the receipt was already entered in the Purchase Order Receipt program, the receipt lines need only be specified with the quantity and stock location information.

The Receipt Quantity Control Maintenance program may also be run in an asynchronous mode to post receipts received through Electronic Data Collection or through the Multi-line Receiving Maintenance program (PO270E).

The EDI Receipt program (ED120E) sends a message to the Purchasing Monitor in order to call PO220E for direct shipments.

The Receipt Quantity Control Detail screen (PO220S03) allows the entry of a number of parcels and counted quantity per parcel. F23 - Split Parcel Lines, allows the user to specify the number of parcels of a specified quantity. Each parcel is then displayed on a separate line with the specified quantity.

The user can receive a purchase order line into a specific location. Although the primary stock location for a part is defaulted from the Part Master file to the stock location field during purchase order receipt, the user may change the value that appears in this field. F23 allows each parcel to be received into a separate location. The location retrieved must be on the Location Validation file (DE140M). The user can also enter a letter or location so that the list of valid locations will start at a particular place.

If a part is location-controlled and Enter is pressed on the receipt screen, the Valid Location file is searched for empty locations in the current company/warehouse. If a location is entered for a part that is location-controlled, the location is checked to ensure it is empty. If the location is not empty, a message is displayed. If Enter is pressed again, the part is received into that location. If the entered location is empty, the line is received into that location. This screen also allows the asynchronous (batch) printing of identification tags. In asynchronous mode, on completion of a receipt transaction, a message is sent to the Purchasing asynchronous monitor to initiate the Identification Tag Print program (PO660E).

For phantom orders, the user is presented with phantom order release information, and receipts against specific releases may be specified. If the phantom order is for a part that had a production type of MRP at the time of the phantom order creation, this updates the labor requirements quantity completed and, if operating under the Shop Floor Control automatic move/receive option, the quantity available for the next operation is updated as well. If the phantom order release selected is for the last operation of a manufacturing order, stock balance information may be entered to process a manufacturing order receipt. A message is sent to the asynchronous monitor and processing is performed by the Manufacturing Order Receipts/Component Issues program (IC130E).

Field display on the detail screen (PO220S03) is determined by the characteristics of the order and part being processed. The display of lot control fields on the detail screen is determined by the system lot control option and the lot option for the part being processed. The display of configuration code is determined by the Expert Configurator Installed flag and the configuration code option for the part. The display of stock balance fields and identification tag printing options is suppressed for direct ship purchase orders and reference parts (part type = 5). For reference parts, the requesting department on the purchase order line is displayed.

The Receipt Inquiry program (PO890E) may be entered by pressing F9 - Inquiry from the Function Select screen. This permits the display of purchase order information if the purchase order number is not given on the bill of lading.

The Purchase Order Maintenance program (PO180E) will be accessed through asynchronous processing if automatic purchase order close processing is performed. The Receipt Quantity Control program will send a message to the Purchasing asynchronous monitor to initiate the purchase order close processing. After the purchase order is closed, the asynchronous monitor will attempt to close the related requisitions. This will occur if the requisition quantity has been fully covered and no other purchase orders cover the requisition.