Documentation >

MAC-PAC Technical Library >

Distribution >

Purchasing >

Programs >

Quality Control and Receipt Adjustment - Purpose

Quality Control and Receipt Adjustment - Purpose

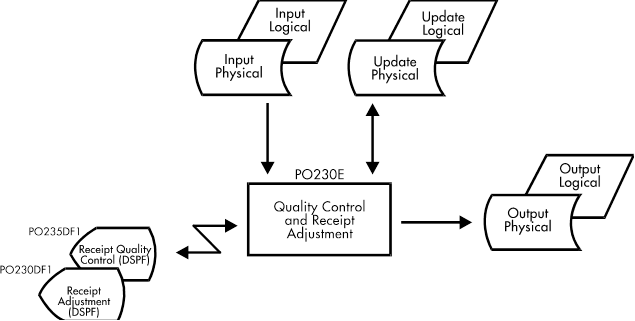

PO230E

The Quality Control and Receipt Adjustment program (PO230E) records the quality disposition of a receipt and updates stock balances under specific conditions. This program is run in one of two modes: Receipt Quality Control processing or Receipt Adjustment processing. The mode is determined by a parameter passed by the calling control language program. The mode determines which set of screens will be displayed and what specific processing will be performed. In a multi-currency environment, the exchange rate is set accordingly.

The transaction processed on the detail screen (PO230S03 or PO235S02) allows the update of the counted, accepted, rework, rejected, return, and non-dispositioned quantities. Stock transfers are processed under certain receipt adjustment codes when the quality control location is being used and a destination stock location is specified. Stock updates without a transfer are also processed when certain receipt adjustment codes are used.

Purchase order lines can be received into a specific location. F21 - Display Stock Location may be pressed to display a list of valid locations from which a valid location can be selected and returned to the detail screen. The location retrieved must be on the Location Validation file (DE140M).

If the part is location controlled, and Enter is pressed on the receipt screen, the Valid Locations file is searched for empty locations in the current company/warehouse. If a location is entered for a part that is location controlled, the location is checked to ensure it is empty. If the entered location is empty, the line is received into that location. If the location is not empty, a message is displayed. If Enter is pressed again, the part is received into that location.

Field display on the detail screen is determined by the characteristics of the order and part being processed. The display of lot control fields on the detail screen is determined by the system lot control option and the lot option for the part being processed. The display of Configuration Code is determined by the Expert Configurator Installed Flag and the Configuration Code Option for the Part. Stock balance fields are not displayed for direct ship purchase orders and reference parts (part type = 5).

For phantom orders, the user is presented with phantom order receipt information and a selection may be made specifying the phantom order receipt to be processed. If the phantom order is for a part that had a production type of MRP at the time of the phantom order creation, the quantity complete on the labor requirement is updated and, if operating under the Shop Floor Control automatic move/receive option, the quantity available for the next operation is updated as well. If the phantom order receipt selected is for the last operation on the order, stock balance information may be entered. This initiates the asynchronous processing of a manufacturing order receipt (or reversal) by the Manufacturing Order Receipts/Component Issues program (IC130E).