Documentation >

MAC-PAC Technical Library >

Distribution >

Order Processing >

Programs >

Bill of Lading Report - Purpose

Bill of Lading Report - Purpose

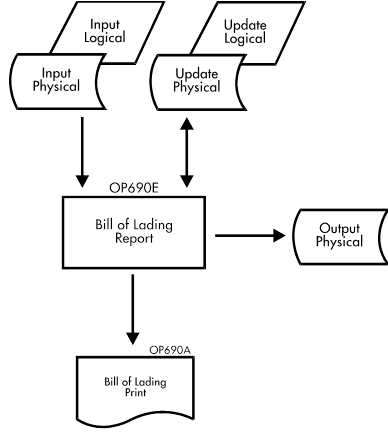

OP690E

The Bill of Lading Report program (OP690E) allows you to print bill of lading documents for each shipment release of an order. Requests to generate this document may be created from several conversations/programs. These are the following:

· Shipping/Billing Asynchronous Update (OP125E)

· Transfer Order Shipping Update (TC125E)

· Bill of Lading Consolidation (CF330E)

· Bill of Lading Report Request (OP310E)

If a shipment release is requested for bill of lading consolidation (the BOL Consolidation flag in shipping/billing must be set to 'Y') the print request for the BOL is not submitted by OP125E but by CF330E. However, the program that submits the print request also assigns the BOL number.

Printing of the bill of lading occurs at the sourcing company/warehouse where the shipping is performed. At that time records are written to the BOL Transaction workfiles (OP690AP1-3). A new BOL Transaction Header Record (OP690AP1) is written if the sourcing company/warehouse changes. One BOL Transaction Line Record (OP690AP2) and one BOL Transaction Lot Record (OP690AP3) is written per every line shipped. If the part shipped is lot assignable or lot controlled, the lot number is formatted on OP690AP3.

The program can run in Asynchronous as well as in batch mode. The mode the print request needs to be processed in depends on the BOL release code the user specifies in the BOL parameter window (BOLPRTWIN) in the shipping conversation or on the Function Select screen of Bill of Lading Consolidation and Bill of Lading Report Request. Related to that code a trigger record is written to the BOL batch trigger file (OP310HP) on the BOL Asynchronous Trigger Record (OP690BP). If the code is 'H' (hold indefinitely) no record is written. Also a record is written to the BOL Transaction file (OP690BP2) for every sales order (or multiple sales orders for a consolidation BOL) associated with that BOL. This record contains the different BOL document format codes. Depending on the document format codes, up to four copies can be generated for a BOL. The document format codes are entered on the BOL Parameter Window (BOLPTS01), the detail screens of BOL Consolidation, or the BOL Report Request screen.

The program also formats the Outbound EDI Shipment transaction files (OP695AP1-3) if the document format code requests an EDI transaction for a specific copy ('E' or 'B'). Each copy can be generated in a different language. The language codes and the network ID's for the different copies are stored on the BOL Transaction Header file. The first copy belongs to the ship-to customer of the sales order. If this is a release of direct distribution sales order, this customer will not receive the goods and the copy is just an acknowledgment about shipped items. The second copy is sent to the carrier that is used for that BOL. The third copy is the customs invoice. The extended price for every line that has been shipped is printed in the currency of the bill-to customer. In the case of a direct distribution order, a fourth copy is generated for the direct distribution customer who receives the items.

Depending on the mode in which OP690E is called, it reads through the BOL Batch Trigger file or the BOL Asynchronous Trigger file. It then chains to OP690BP2 to get the first record related to that BOL by using the BOL number. Header information is retrieved from OP690AP1 for the first record and printed. It then processes sequentially all records of OP60AP2 associated with the BOL number and sales number. If the item is lot controlled it reads lines from OP690AP3. The line information is printed on the BOL copies. Comments are retrieved from the Shipping/Billing Comment file (OP120AP2).

If the order/line is for a configured order, sales order line options are retrieved from the Sales Order Options file (EC200M) and price detail information is retrieved from the Sales Order Price Detail file (EC240AP) and printed on the bill of lading.

If the Job Control module is installed, job information for the shipment is printed on the bill of lading. If all lines for that sales order have been processed, shipment totals are printed. The next chain to OP690BP2 is performed in order to find another sales order with the same ship-to customer related to that BOL number. If no other sales order is found, ship-to customer totals are printed. The next chain looks for sales orders with the same currency, and if no other sales orders are found, country totals are printed. Before printing the sales order information or formatting the EDI transaction files for a specific copy of the BOL, the document format code is checked in order to verify if this shipment should be printed or sent via EDI. After all records of OP690BP2 related to that BOL number have been processed, bill of lading totals are printed.