Documentation >

MAC-PAC Technical Library >

Distribution >

Order Processing >

Programs >

Automatic Order Release - Purpose

Automatic Order Release - Purpose

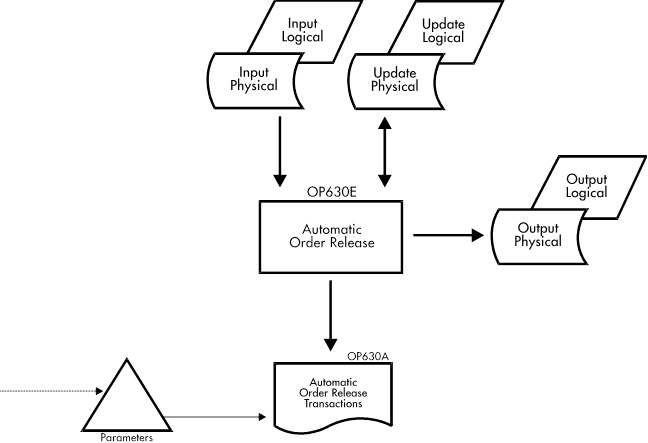

OP630E

The Automatic Order Release program (OP630E) is called by the Automatic Order Release command language program (OP630C) when the automatic order release job is submitted from the Order Processing Menu. It processes orders that meet the criteria entered and validated online through the Automatic Order Release Request program (OP340E). Before calling this program, the command language program reads the request file (OP340AP1) and issues an Open Query File (OPNQRYF) command to select records from the Order Header file (OP100M1) that meet the entered criteria.

The Automatic Order Release program performs the following functions for the following types of orders:

Credit Held Orders: These orders are credit checked again. If the order is no longer credit held, it is processed as a normal order.

Future Orders: If the order status is open, implying a picker has not been generated, the Automatic Order Release program will attempt to reserve more stock for the order. If the order status is released or partially shipped, implying a picker has generated, a new release will be created for any items for which a picker should be created. Promised ship dates are generated for subsequent releases.

Blanket Orders: Selected orders are tested to determine whether a new release needs to be created. If so, a release is created and stock is reserved for that release.

Back Orders: Where there is stock available a new release is created and stock will be reserved for that release. If there is no need to create a new release (the picker has not been printed for a specific shipment) the reserve quantity is increased.

Ship Complete Orders: More stock is reserved for these orders until the order is fully reserved.

The Automatic Order Release program may be submitted for the above types of non-EDI orders via the Automatic Order Release option on the Order Processing Menu. Only orders with an EDI flag (SHEDFL) value of no are processed. EDI orders (EDI flag value of yes) may also be processed by the Automatic Order Release program. The program is called within the EDI Batch Sales Order Entry job stream (ED140E) for every sales order created. If the EDI Sales Order Generation program (ED140E) ends abnormally, the Automatic Order Release program may still be used for EDI orders via the EDI Automatic Order Release option on the Order Processing Menu.

All orders will be credit checked depending on whether Reference File category D38 has been set up to trigger credit checking in the Automatic Order Release program.

Orders are considered for stock reservation in order of backorder priority code and then order date. The Sales Order Header file will be preprocessed by control language program OP360C using an Open Query File (OPNQRYF) command to filter out records according to user selections, and to arrange records in the correct sequence. An audit trail report describes actions performed on each order.

As orders are processed, if Outstanding Orders reports have been requested, records will be written to the Outstanding Orders Transaction file (OP630AP1) and the Backordered Items Transaction file (OP630AP2).

This program can also be called by the Manufacturing Receipt program (IC130E) when the automatic order release flag on Reference File category Y35 is yes. After a successful receipt of a lot assignable, configuration coded part (PMCFCO not equal to 0) in a manufacturing order that was created by the configurator, the quantity, stock location, balance type, and lot number are passed to OP630E. OP630E then reserves the newly received quantity for the sales order that created the manufacturing order.

In order to service backorders more quickly when supply of a specific item is received, this program can also be called by the Backorder Release by Part program (OP380E). If a request is submitted immediately, the company, warehouse, and part number are passed to OP630E. (The source-from warehouse and promised ship date range may also be passed, but both are optional). If a request is submitted in Batch mode, the Backorder Release by Part Request file (OP310IP) is populated. When the job is submitted, OP630E will process all parts requested (either the part passed in the parameter list or the parts requested in OP310IP). Releases will be created if stock is available and if the order is released (the picker has been printed). If the order has not been released (the picker has not been printed), more inventory will be reserved if available. If the optional promised ship date range was entered, only those sales orders within that range will be processed.

This program can also run in another mode: Multi-line Inventory Reservation. The program will now process the requested changes made to sales order lines in the online Multi-line Inventory Reservation conservation (OP165E). These requests to decrease inventory, increase inventory, or change a date that will affect inventory reservation are stored on the Multi-line Inventory Reservation Update Request file (OP165AP4). The Multi-line Inventory Reservation Batch Update program (OP635E) will call this program for every sales order line to be processed. Auto Order Release will process only one sales order line at a time, and will either increase inventory, decrease inventory, create a backorder release, or change a date and adjust the reserved/backordered inventory accordingly.