Documentation >

MAC-PAC Reference Library >

Manufacturing >

Shop Floor Control >

Key Concepts and Procedures >

Bar Coding >

Bar Coded Features in Shop Floor Control

Bar Coded Features in Shop Floor Control

Requests for bar coded documents can be made online in Shop Floor Control. The requests are by manufacturing order for any of the following:

Setup Ticket

The Labor Setup Ticket is used to report the time spent by employees in setting up or preparing machines and processes.

Labor Ticket

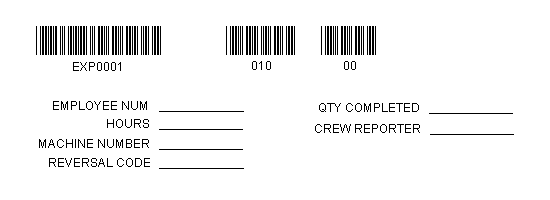

The Direct Labor Ticket (shown below) is used to report direct labor hours worked at an operation within a manufacturing order.

Direct Labor Ticket

Move Ticket

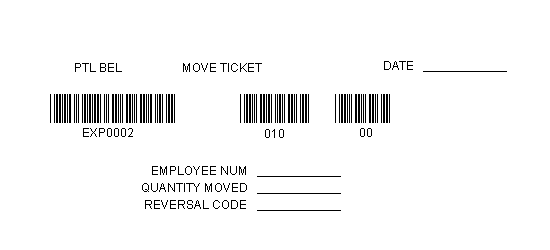

The Move Ticket is shown below. It is used to report the quantity moved from one operation, and to initiate the move to the following operation.

Move Ticket

Receive Ticket

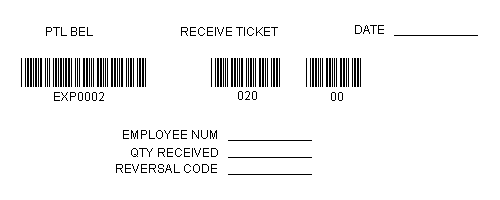

The Receive Ticket is used to acknowledge the quantity received from a prior operation, and to update the quantity available for the receiving operation. It is shown in the illustration below.

Receive Ticket

The information on labor, setup, move, and receive tickets is used in the labor requirements update conversation to enter (online): hours worked, quantity moved, and quantity available. Information such as the employee number, which is required by the labor requirements update conversation but can only be determined at the time the transaction is raised, is not bar coded by the system. It may still be entered from bar code charts. Each work area on the shop floor could hold the relevant static information pertaining to its unique operations on such bar code charts.