Documentation >

MAC-PAC Reference Library >

Manufacturing >

Master Scheduling >

Key Concepts and Procedures >

Multi-Level Forecast Generation

Multi-Level Forecast Generation

Multi-Level Forecast Generation will create projected demand records for component parts based on the projected demand quantity of the parent parts. The forecast of the parent part will be exploded down through all levels of the bill of material to create forecast records for the component parts. The quantity per, batch quantity, part master scrap factor, and product structure scrap factor will be taken into account when the forecast quantity is calculated. The lead time and offset days will be taken into account when the forecast date is calculated.

Forecast records will not be created for build-thru parts, produced parts, or parts that are reference parts on the bill of material. The Multi-Level Forecast flag on the part master of the parent and the component must be set to Y (yes) for the forecast to be exploded. This flag can be maintained on the Configuration screen of Part Master Maintenance. Only non-Future III forecasts from the manufacturing company warehouses will be exploded.

The Multi-Level Forecast Generation Report (MS130) lists all the parts processed for each plant.

The following example illustrates Multi-Level Forecast Generation processing.

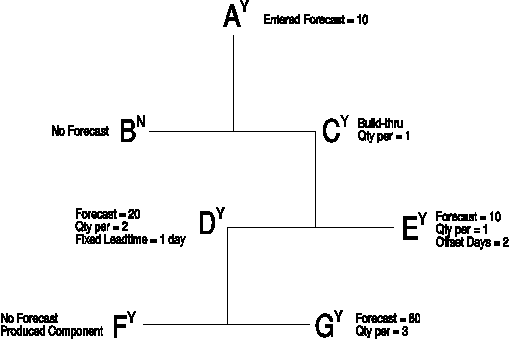

A bill of material is defined for the following parts as shown. The 'Y' or 'N' indicates the value of the Multi-Level Forecast flag for the part. A forecast of 10 is entered for part A. Multi-Level Forecast Generation is run.

Sample Bill of Material Used in Multi-Level Forecast Generation

The results of the Multi-Level Forecast Generation are as follows:

· No forecast is generated for part B because its Multi-Level Forecast flag is N.

· No forecast is generated for part C because it is a build-thru part.

· The forecast generated for part D takes into account the quantity per factor of 2.

· The forecast generated for part E takes into account the quantity per factor of 1. Because of the offset days, the forecast date of E is 2 days before the due date of A.

· No forecast is generated for part F because it is a produced component.

· The forecast generated for part G takes into account the quantity per factor of 3. Because of the leadtime, the forecast date of G is 1 day before the forecast date of D.