Documentation >

MAC-PAC Reference Library >

Distribution >

Electronic Data Interchange >

Key Concepts and Procedures >

EDI Transaction Processing in a CID Environment >

Customer Location Processing

Customer Location Processing

EDI Processing from the Customer Location Perspective

EDI Processing from the Customer Location Perspective

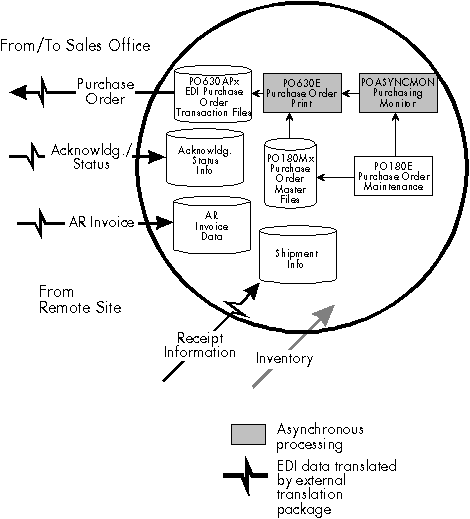

The end customer initiates the entire CID transaction process by sending out a purchase order. This location can also receive data from both the sales office and remote site related to the purchase order. This information can be transmitted via EDI transaction files. There are three EDI transactions are supported; they are sequenced in a list below.

1. Outbound Purchase Orders

2. Inbound PO Acknowledgments

3. Inbound Receipts

Outbound Purchase Orders

The first step in computer integrated distribution is to process an initial purchase order that is sent from a customer location to a sales office (via PO630E). Outbound purchase order transactions can be generated asynchronously or in batch, depending on the release code of the purchase order. They may also be regenerated, if necessary. When EDI processing is used, the Purchase Order Document Format field must allow EDI transmission (the value must be "E"-electronic transmission only or "B"-both paper copy and electronic transmission).

Once a purchase order transaction is sent to the sales office, it can be converted into an inbound sales order on the sales office's system (via ED140E if this location has MAC-PAC). Comments related to the outbound purchase order can also be transferred to the subsequent sales order.

Inbound Purchase Order Acknowledgments

Once you send a purchase order to the sales office, that office will go through several processing steps. One of the choices that the sales office has to make is whether they are going to source the inventory or have it sourced from a remote vendor or site. Regardless of the decision, you will want to know that your order has been received and is being processed. This information is confirmed by sending purchase order acknowledgment status data (on the sales office's system this is processed as an outbound sales order acknowledgment, at your location this data can be used to process an inbound purchase order acknowledgment). In addition to confirming receipt, these files contain the date when the vendor expects to ship the order.

Inbound purchase order acknowledgments are only confirmed by the sales office. Therefore, regardless of where the order is sourced, you will receive information from the location to which you sent the original purchase order. If the order was sourced remotely, the remote site (once they have received and processed the sales order) will send a copy of an outbound sales order acknowledgment to the sales office. The information contained in the acknowledgment files is an update of all the processing that has occurred since you initiated the transaction. If they choose, the sales office can forward this information to you. You can use this information to update your records.

Note: You can define the company/warehouse, ship-to customer, and bill-to customer information for each vendor defined on the system. This information is used by the vendor to identify purchase orders received from this site. There is no system validation when you enter the field on the EDI Information screen in the Vendor Master Maintenance conversation; however, it is used later to validate vendor information when processing inbound EDI purchase order acknowledgments and receipts. If these fields are blank, the first vendor with blank external fields is used.

Follow-up transactions may occur if the sourcing warehouse changes the ship date. Again, this information would be sent to you from the sales office. Both types of transactions, the initial acknowledgment and the later status updates, are processed identically.

Inbound Purchase Order Receipts

Once your order is ready for shipment, the sourcing site (the sales office or the remote site) will initiate an outbound shipment/BOL transaction. These resulting inbound receipt files confirm the shipment date and the quantities of the order. This information can be sent to your location (usually in the form of a BOL) in either paper or electronic format and can be used to update your records.

If the order has not been sourced remotely, the receiving information¾in the form of a BOL¾and the actual shipment of inventory can be sent together from the sales office to you (the customer location). If, however, the order has been sourced remotely by the sales office and they (the sales office) have requested that the shipment be sent directly to you from the remote site, you will still be able to process an inbound receipt and an inbound shipment transaction. The only difference is that the information you use to process these transactions will come from the remote site. A shipment transaction is sent directly from the remote sourcing site to you, bypassing the sales office completely. This shipment transaction will be accompanied by a BOL (in paper format or via EDI as inbound receipt data).

Note: You can define the company/warehouse, ship-to customer, and bill-to customer information for each vendor defined on the system. This information is used by the vendor to identify purchase orders received from this site. There is no system validation when you enter the field on the EDI Information screen in the Vendor Master Maintenance conversation; however, it is used later to validate vendor information when processing inbound EDI purchase order acknowledgments and receipts. If these fields are blank, the first vendor with blank external fields is used.