Documentation >

MAC-PAC Reference Library >

Manufacturing >

Transfer Control >

Key Concepts and Procedures >

Transfer Requisitions >

Automatic Requisition Generation

Automatic Requisition Generation

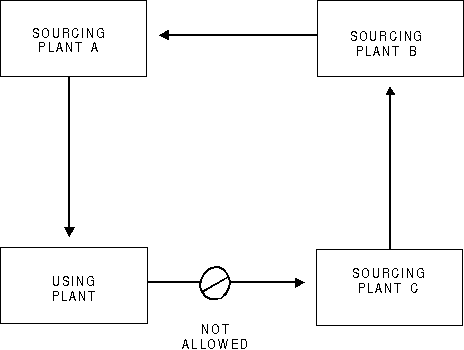

The planning modules (Master Scheduling and Requirements Planning) automatically create transfer requisitions to meet demand for transfer parts. Transfer parts (part type 8) are defined using the Part Master Maintenance conversation in the Design Engineering module in the same way as other part types. However, for transfer parts a sourcing plant must be defined, distinct from the plant that uses the part. The part must then be defined in the sourcing plant as a manufactured, build-thru, purchased, raw material, or transfer part. If the part is defined as a transfer part in the sourcing plant, another sourcing plant must be defined. This kind of transfer chain is allowed by the system, as long as the sourcing plant at the end of the chain is distinct from all other sourcing plants in the chain (see the figure below). This rule allows the planning modules to determine which warehouse will ultimately supply the part in order to plan requirements and supply appropriately.

A transfer part has the same characteristics as a manufactured part in that it can have a bill of material and routing.