Documentation >

MAC-PAC Reference Library >

Manufacturing >

Transfer Control >

Key Concepts and Procedures >

Description

Description

The Transfer Control module helps you track the transfer of inventory between warehouses. It provides detailed online conversations and reports that allow you to enter, maintain, and track data related to all aspects of the transfer process.

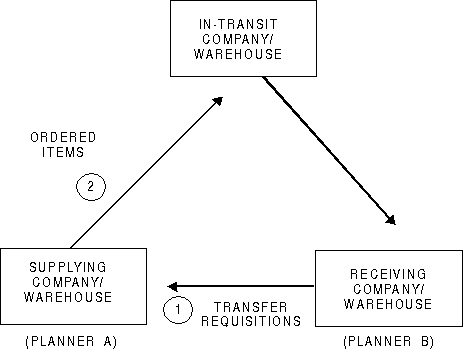

Example of Transfer Scenario

A typical transfer scenario is illustrated above. A planner in the receiving company/warehouse (planner B) creates transfer requisitions, usually after having used inventory inquiries to determine which company/warehouse is most likely to be able to supply the items required. The planner in the supplying company/warehouse (planner A) reviews all requisitions made against his or her company/warehouse and creates transfer orders to satisfy them. Ordered items are shipped to the receiving company/warehouse. Between shipment and receipt, the items are assigned to an in-transit company/warehouse (for tracking purposes only).

As the illustration shows, the transfer process begins with the creation of transfer requisitions. These requests for inventory transfer may originate with inventory control personnel at a warehouse. Or, for items that have been defined as transfer parts in the Design Engineering module, requisitions may be generated automatically by the MAC-PAC planning modules (Master Scheduling and Requirements Planning). Transfer requisitions contain information such as the supplying and receiving company/warehouses, the item number and quantity of the item needed, the date the inventory is required, and inventory balance types the item will be relieved from and supplied to. Transfer requisitions may contain several lines, each representing a separate transfer request.

Transfer orders are used to fill, or cover, transfer requisitions. An online transfer order entry conversation allows the inventory planner at the supplying company/warehouse to enter detailed information about how the order should be handled (for example, delivery address, free on board code, required date, and shipping specifications), and then select which requisitions will be covered on the order. Several requisitions may be covered by a single transfer order, and several requisition lines (requesting transfer of the same item) may be covered by a single transfer order line. The planner may also order items for which no requisitions exist, or may order a greater quantity of the requisitioned items than was originally requested.

When appropriate, the Transfer Control module generates all the required paperwork for the inventory transfer, including the picking document and the expected shipments and receipts reports. When a transfer order is shipped, a user at the supplying company/warehouse enters the quantity shipped against a transfer order line. Several shipments may be made against a single line. When a transfer order shipment is received, a receiving clerk uses an online conversation to record it. Several receipts may be recorded against each transfer order shipment. If inventory is lost or damaged during transfer, shrinkage quantities can be entered when the receipts are entered, or shrinkage can be calculated automatically when a transfer order line is closed.

Invoices may be created during the Transfer Order Shipping process when goods are shipped across EEC borders. If you are using ESL/SSD report processing, during Transfer Order Maintenance and Transfer Order Shipping, you may choose to generate pending invoices and the necessary accounting transactions when the transfer order shipment is processed. Invoiced transfer order shipments will be printed on the European Sales List (ESL) and Supplementary Sales Declaration (SSD) reports. This information is necessary for inter-country VAT declaration purposes in the EEC.

In a multi-plant, just-in-time environment where time frames do not permit the typical transfer scenario, the Transfer Control module enables stock transfers between a supplying company/warehouse and receiving company/warehouse with minimum transactions and paperwork. An online multi-plant requisition transfer conversation allows planners to reduce planned transfer requisition quantities immediately and to transfer inventory directly. No transfer orders (and thus no paperwork, pickers, etc.) and no in-transit warehouse structure is utilized. In addition, pending invoices will not be processed for the transfers.

Detailed information about the processes described above may be found in the Key Concepts section of this manual. The rest of this section describes the unique features of the module, as well as inputs, outputs, and key master files.