Documentation >

MAC-PAC Reference Library >

Manufacturing >

Just-in-Time >

Key Concepts and Procedures >

Just-in-Time Fundamentals >

Production Centers

Production Centers

Just-in-Time production also strives to reduce unnecessary effort by redesigning the typical MRP shop floor. By replacing some workcenters with production centers, a JIT operation saves on time, effort, and space.

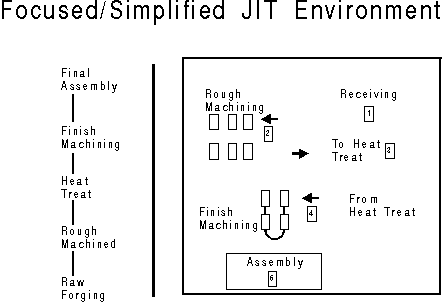

A production center is a set of machines, dedicated to manufacturing one or several similar parts. Production centers are arranged sequentially on the shop floor so that as components leave one center, they are moved only a short distance to the next stage of production. This arrangement differs from an MRP shop floor, where machines are grouped by type, regardless of which parts they process. The JIT shop floor model is illustrated below.

Just-in-Time Shop Floor Model

Each JIT part is assigned to a production center on the Part Master File. However, parts may be scheduled in alternative production centers as long as the part master production center is in the same production family as the alternative production center. This family is defined on the Production Center File. Production center capacity is measured in average daily part production, including all parts produced at the center on a given day. This allows the system to display daily load and performance information. Daily/weekly production schedule maintenance is performed by production center for all parts that may be produced in a particular center. A part may be added to an alternative production center through this conversation. Part production schedule maintenance is performed by part, for all centers that belong to the same production center family as the part's main production center.

Parents produced by a production center are received into warehouse stock locations. Simultaneously, components are issued from warehouse stock locations. These locations are defined by part so that two parts using the same production center may have different issuing/receiving shop floor or warehouse stock locations. For those parts scheduled in alternative production centers, these locations may be retrieved from the Part/Production Center Relationship File, if a relationship is defined for the alternative center.