Documentation >

MAC-PAC Reference Library >

Distribution >

Purchasing >

Key Concepts and Procedures >

Requisition Processing >

Requisition Status

Requisition Status

The requisition status defines the life cycle of a requisition. The requisition status code can be one of the following values:

· Planned. The requisition has been created by Requirements Planning or Master Scheduling. If the Automatic Purchase Order Creation Flag on the Part Master record is Yes (Y), the requisition is ready to be covered by a purchase order.

· Firm Planned. The requisition line makes the requisition amount exceed the maximum authorized requisition amount for a manually entered requisition, and the user is not authorized to release requisitions.

· Released. The requisition has been approved for purchase order covering, or has been entered manually.

· Closed. The requisition has been manually closed by the analyst under covered quantity conditions.

· Cancelled. The requisition has been canceled using a maintenance function; this status is available only if the requisition is not already being covered.

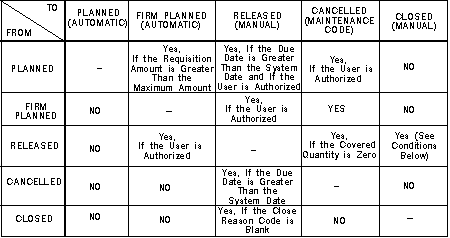

The figure below shows all possible values for the requisition status and all authorized changes.

Requisition Status Values and Possible Changes

The planned requisition status is automatically assigned by the Requirements Planning or Master Scheduling application. A requisition status cannot be manually changed to planned.

The firm planned requisition status is automatically assigned by the system for manually entered requisitions when the current requisition line makes the requisition amount exceed the maximum authorized amount and if the user is not authorized to release the requisition. This maximum amount is user defined in the Purchasing System Defaults category on the Reference File. The firm planned status can be changed only to released or closed status and only by an authorized user. Authorized users are defined in the Requisition Release Authorization category on the Reference File. A requisition status cannot be manually changed to firm planned.

The released requisition status is automatically assigned by the system in a manual requisition creation. It can be manually set from planned to released by the analyst who wants the requisition to be covered by a purchase order. If the Automatic Purchase Order Creation Flag on the Part Master record is Yes (Y), planned requisitions may be automatically treated during the Purchase Order Maintenance Conversation. Otherwise, if the flag is No (N), the requisition status must be manually changed from planned to released before it can be treated in Purchase Order Maintenance.

The canceled requisition status, K, is automatically assigned by the system when entering the requisition line number and a line maintenance code equal to X (cancel). It can then be manually changed only to released by entering the requisition line number and a line maintenance code of R (reinstate). A canceled requisition is not taken into account by the Requirements Planning and Master Scheduling applications. A requisition line can be canceled only if the covered quantity equals 0.

The closed requisition status may be set manually under two conditions:

· A close reason code must be entered.

· The difference between the requisition quantity and the covered quantity must be less than the total requisition quantity multiplied by the close tolerance percent.

The close reason code must exist on the Reference File. The code description explains the reason the requisition was closed. These codes are all user defined. The close tolerance percent is defined:

· At system level on the Reference File (Purchasing System Defaults category)

· At purchasing group level on the Reference File (Purchasing Group Codes category).

A closed requisition can only be changed to released; the close reason code must simultaneously be removed. It is not taken into account by the Requirements Planning and Master Scheduling applications when it is closed.

All of these status codes are defined in the Requisition Status Codes category on the Reference File.