Documentation >

MAC-PAC Reference Library >

Distribution >

Order Processing >

Key Concepts and Procedures >

Order Information >

Order Date Calculations

Order Date Calculations

When an order for goods is entered into the system, several dates must be calculated before the order can be fully processed and shipped. These dates are either entered directly at order entry time or automatically calculated by the system. They include:

· Requested Dock Date

· Required Ship Date

· Promised Ship Date

· Expected Receipt Date

Note: In a client/server environment, the following dates are entered and calculated by MAC-PAC on the server. If you are using the Sales Force Automation module to enter remote orders, the date processing is slightly different. In that case, the client dates map to the server dates; once these dates are mapped to the server, they are processed using the calculations specified in the Sales Force Automation On-line Help System.

See the Order Release and Picker Information key concept for further explanation of internal and external lead times.

Requested Dock Date

This is the date the customer wants the goods to arrive on their dock. If a customer gives you a requested dock date, the order is backward-scheduled from that date. In this case, the external lead time is subtracted from the requested dock date to determine the required ship date. If a customer does not give you a requested dock date, the order is forward-scheduled from the current date. In this case the internal lead time is added to the current date to calculate the required ship date.

Required Ship Date

This is the date that you must ship an order's goods so that they arrive at the customer's dock by the requested dock date. This date is either calculated by back-scheduling from the requested dock date (if entered) or by forward-scheduling from the current date (if no requested dock date entered). The internal lead time, which is the time it takes for you to package and prepare your goods for shipment, is used if the order is forward-scheduled. The external lead time, which is the time it takes for goods to leave your warehouse and arrive at the customer's dock, is used if the order is backward-scheduled.

Promised Ship Date

This is the date you intend to ship the goods. It is used throughout the system as a basis for tasks such as automatic order release and picker printing. It drives demand throughout the planning modules (Requirements Planning and Master Scheduling), scheduling inventory to be available one day before the promise ship date. When originally entered, it is saved in the Original Promised Ship Date field and is maintainable on each order line. The Original Promised Ship Date field is mainly used to document changes in the promised ship date.

The calculation of the promised ship date is based on two other dates: the required ship date and the earliest possible shipping date. As orders are entered, the required ship date is calculated. Then, the earliest possible shipping date is calculated by adding the internal lead time to the current date. The earliest possible shipping date is held in a work field; it is not enterable or visible.

Once both the required ship date and the earliest possible shipping date are calculated, the main consideration is whether the customer's requested dock date be met. If the goods can be shipped by the required ship date (e.g., the earliest possible shipping date is earlier than the required ship date) then the customer's requested date can be met. In this case, the promised ship date is set to the required ship date.

If the goods cannot be shipped by the required ship date (e.g., the earliest possible shipping date is later than the required ship date) then the customer's requested date cannot be met. When this happens, the value of the Customer Drives Date flag held on the Customer Master file determines the value of the promised ship date.

· If the Customer Drives Date flag is set to Y-Yes, the promised ship date is set to the required ship date even though it appears that the date cannot be met. This implies a rush situation and must be handled by following your internal procedures.

· If the Customer Drives Date flag is set to N-No, the promised ship date is set to the earliest possible shipping date.

Note: Once the promised ship date is calculated, it can be overridden by the order entry person.

Expected Receipt Date

This is the date the customer can expect to receive the goods. It is calculated by adding the external lead time to the promised ship date.

Examples of Date Calculations

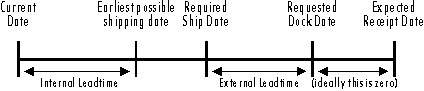

Below are several examples of order date calculations. In the first example, the customer does not supply a requested dock date. In the second example, the customer supplies a requested dock date that can be met. In the third example, the customer supplies a requested dock date that cannot be met. In all of the examples, assume that you have selected the standard part distribution lead time for internal lead times and the ship-to customer lead time for external lead times on Reference File category 412. Furthermore, you have set these lead times to 3 days for internal and 5 days for external. The following figure shows a reference time line of the order dates.

Time Line of Order Dates.

Notice that the earliest possible shipping date is earlier than the required ship date. That may not always be the case, depending on the length of the internal lead time and the customer's requested dock date.

No Requested Dock Date

On December 9, customer SAM's HARDWARE orders ten thousand bolts. SAM's HARDWARE does not request a specific date for delivery and therefore the requested dock date is left blank on the order.

|

|

|

|

|

Current Date

|

12/09/94

|

Default

|

|

Requested Dock Date

|

-blank-

|

None

|

|

Required Ship Date

|

12/12/94

|

12/09/94 + 3 days

|

|

Earliest possible ship date

|

12/12/94

|

12/09/94 + 3 days

|

|

Promised Ship Date

|

12/12/94

|

Set to Required Ship Date

|

|

Expected Receipt Date

|

12/17/94

|

12/12/94 + 5 days

|

Order Date Calculations with No Requested Dock Date.

Since the earliest possible shipping date is equal to the required ship

date, the promised ship date is set to the required ship date.

Requested Dock Date That Can be Met

On December 9, customer SAM's HARDWARE orders ten thousand bolts. SAM's HARDWARE requests that the bolts be delivered in time for Christmas. They would like them by December 12/19/94.

|

|

|

|

|

Current Date

|

12/09/94

|

Default

|

|

Requested Dock Date

|

12/19/94

|

Requested by customer

|

|

Required Ship Date

|

12/14/94

|

12/19/94 - 5 days

|

|

Earliest possible ship date

|

12/12/94

|

12/09/94 + 3 days

|

|

Promised Ship Date

|

12/14/94

|

Set to Required Ship Date

|

|

Expected Receipt Date

|

12/19/94

|

12/14/94 + 5 days

|

Order Date Calculations with a Requested Dock Date that Can be Met.

Since the earliest possible ship date is earlier than the required ship date,

the promised ship date is set to the required ship date.

Requested Dock Date That Can Not be Met

On December 9, customer SAM's HARDWARE orders ten thousand bolts. SAM's HARDWARE requests that the bolts be delivered in time for Christmas. They would like them by December 12/15/94.

SAM's HARDWARE is a valued customer and you wish to do everything you can to keep their business. Because of this, you have set the Customer Drives Dates flag on SAM's HARDWARE's customer record to Y-Yes. This means that even if the earliest possible shipping date is later than the required ship date, the promised ship date will be set to the required ship.

|

|

|

|

|

Current Date

|

12/09/94

|

Default

|

|

Requested Dock Date

|

12/15/94

|

Requested by customer

|

|

Required Ship Date

|

12/10/94

|

12/15/94 - 5 days

|

|

Earliest possible ship date

|

12/12/94

|

12/09/94 + 3 days

|

|

* Promised Ship Date

|

12/10/94

|

Set to Required Ship Date

|

|

Expected Receipt Date

|

12/15/94

|

12/10/94 + 5 days

|

Order Date Calculations with a Requested Dock Date that Cannot

be Met.

Since the earliest possible ship date is later than the required ship date and

the Customer Drives Dates flag on the Customer Master file is Y-Yes, the

promised ship date is set to the required ship date.

Note: Since the promised ship date is earlier than the earliest possible ship date, you have a rush situation that must be handled by following your internal procedures.